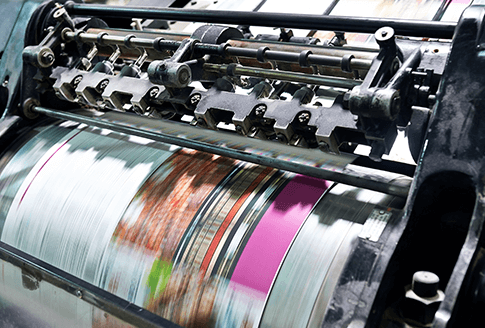

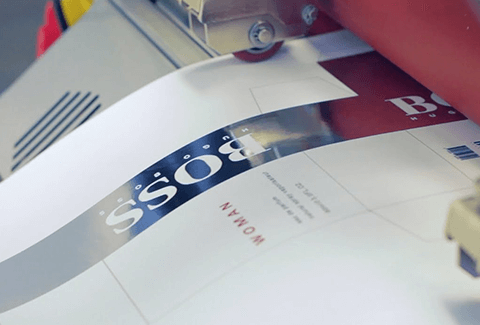

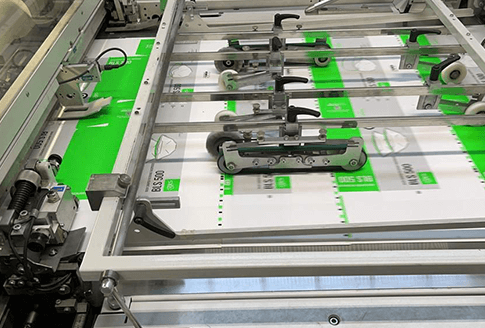

Prepress is the process of preparing digital files for a printing press—making them ready for printing. Our prepress department reviews the client’s electronic files and make adjustments to them to make them compatible with printing on paper or other substrates on ArtisoCAD. High-End Kongsberg samplemakers for accurate cutting and creasing of instant dummies. Our state of the art equipment, up to date software and highly skilled technicians not only ensure that customer’s requirements are adhered with regards to colour and graphic reproduction, but also assure optimal cost and production feasibility.