Carton manufacturing is a very innovative industry, although we have a few structurally universal carton types. The aesthetics can vary depending upon the product to be packaged, but the core skeleton of the carton more often than not remains the same.

So what are the different types of folding cartons?

Broadly we can classify the folding cartons in 5 categories as mentioned below

- 1

Straight Tuck-in

- 2

Reverse Tuck-in

- 3

Self-lock bottom

- 4

Lock-bottom

- 5

End glue

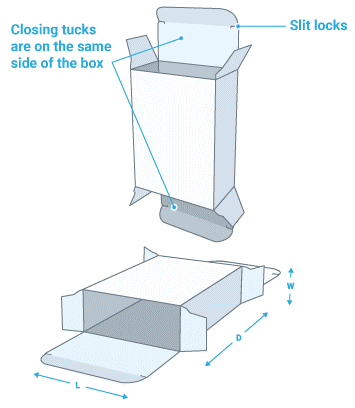

Straight Tuck-in

More commonly known as STI amongst packaging manufacturers. Straight tuck-in boxes are one of the most common types of boxes that work for a variety of industries. The top and bottom closure panels are attached to the same main panel.

A straight tuck box folds from front to back in the same direction. Usually, a straight tuck-in box has slit locks that secure the tucks in place.

Straight Tuck-in Box Features

- Ideal for light weight and medium weight products.

- Zero assembly needed.

- Compact storage (boxes come in flat).

- Can hold cutouts without. compromising integrity.

- Slit locks for secure closing.

- Cost per piece a bit higher than Reverse Tuck because they don’t “nest” on the paper sheet as well, and thus more paper is used.

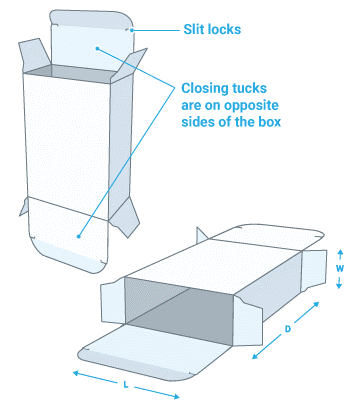

Reverse Tuck-in

More commonly known as RTI amongst packaging manufacturers. Reverse tuck-in boxes are very similar to straight tuck-in boxes, except for the closing panels. One closing panel is attached to the back of the box, while the other closing panel is attached to the front. They fold in opposite directions.

Reverse Tuck-in Box Features

- Ideal for light weight and medium weight products.

- Zero assembly needed.

- Compact storage (boxes come in flat).

- Can hold cut-outs without compromising integrity.

- Slit locks for secure closing.

- Cost per piece lower than straight tuck boxes - RT “nest” better, maximizing costs and efficiency on the printing sheet.

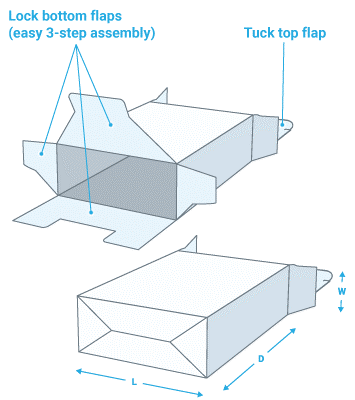

Self-lock bottom cartons

Also called 1-2-3 bottom boxes or self-lock bottom boxes in the packaging manufacturers circle, are especially designed to hold heavier items. The bottom flaps push into each other, forming a very sturdy base that won’t open under the weight of the product inside. For the top closure, they generally have a tuck top panel with either friction locks or slit locks.

Lock Bottom Box Features

- Ideal for heavier products (candles, glass jars)

- Usually with a tuck top closure

- Easy three-step assembly

- Compact storage (boxes come in flat)

- Can hold cutouts without compromising integrity

- Items stack perfectly thanks to the flat bottom

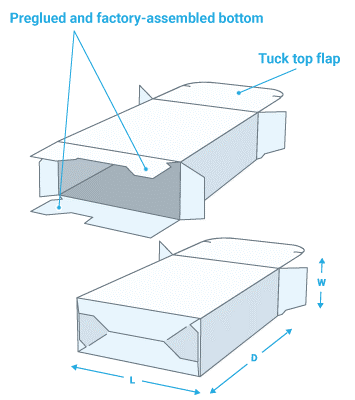

Lock bottom cartons

Lock bottom, are another good choice to package heavier items that need extra bottom support. They are also referred to as auto-lock bottom boxes, or auto-bottom boxes amongst the packaging manufacturers.

Lock bottom Box Features

- The strongest option for heavy products

- Pre-glued bottom for extra strength

- Usually with a tuck top closure

- Zero assembly needed, just "pop" them open

- Compact storage (boxes come in flat)

- Can hold cut-outs

- Items stack perfectly thanks to the flat bottom

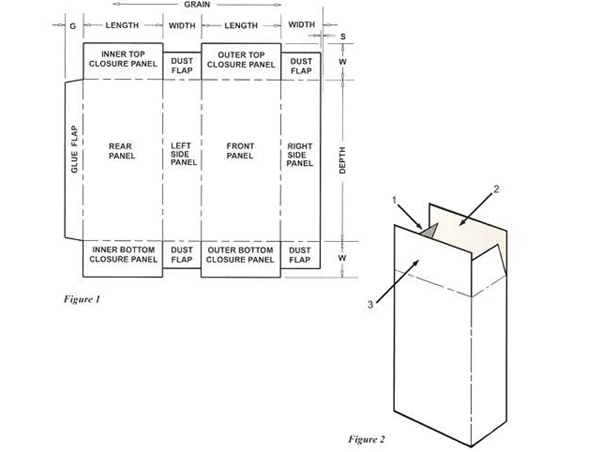

End Glue Cartons

These cartons are essentially used for packaging of food products on automatic packaging lines. Both ends of these cartons are glued after filling the product in the carton.

End glue carton features

- Items stack perfectly

- Pilferage and adulteration can be controlled

- Packing has to be on automatic lines

- Liners with barrier properties can be used to avoid moisture or any other contamination

- Compact storage (boxes come in flat)

Folding cartons are the workhorse of the modern-day product packaging industry. They’re cheap to produce, easy to work with, and are environmentally sustainable. Near limitless options for customization ensure your product packaging reflects your brand’s personality perfectly.

Decoding Sustainable Packaging

Prev post

Decoding Sustainable Packaging

Prev post

Recent Posts

- Folding Carton Styles Explained – find the right choice for your product

- Decoding Sustainable Packaging

- How is printing and packaging affecting the product’s brand value?

- Why are all businesses now spending more time and money on the development/designing of printing and packaging?

- Getting into the core of MK’s certifications